High-quality industrial electrical motors from lepu motor | oem & odm | low moq. lepu motor, providing trustworthy industrial electrical motors , owning many yrs experience, offers the best industrial electrical motors.

High-quality industrial electrical motors from lepu motor | oem & odm | low moq. lepu motor, providing trustworthy industrial electrical motors , owning many yrs experience, offers the best industrial electrical motors.

Get the latest in Exceptional industrial electrical motors at Lepu Motor. Trust Lepu Motor & their industrial electrical motors when you’re seeking industrial electrical motors.

Our jigh-performance industrial electrical motors have a global presence, satisfying customers worldwide.

The value-packed we offer are synonymous with high quality, longevity, and effortless maintenance. Check out our website for extensive details.

Lepu Motor collaborates with universities and Higen Motors, holding nearly 200 patents

Our automated production base, supported by big data and intelligent systems like QMIS, TQM, and FMEA

We provide complete small appliance design, integrating Lepu Motor’s technology

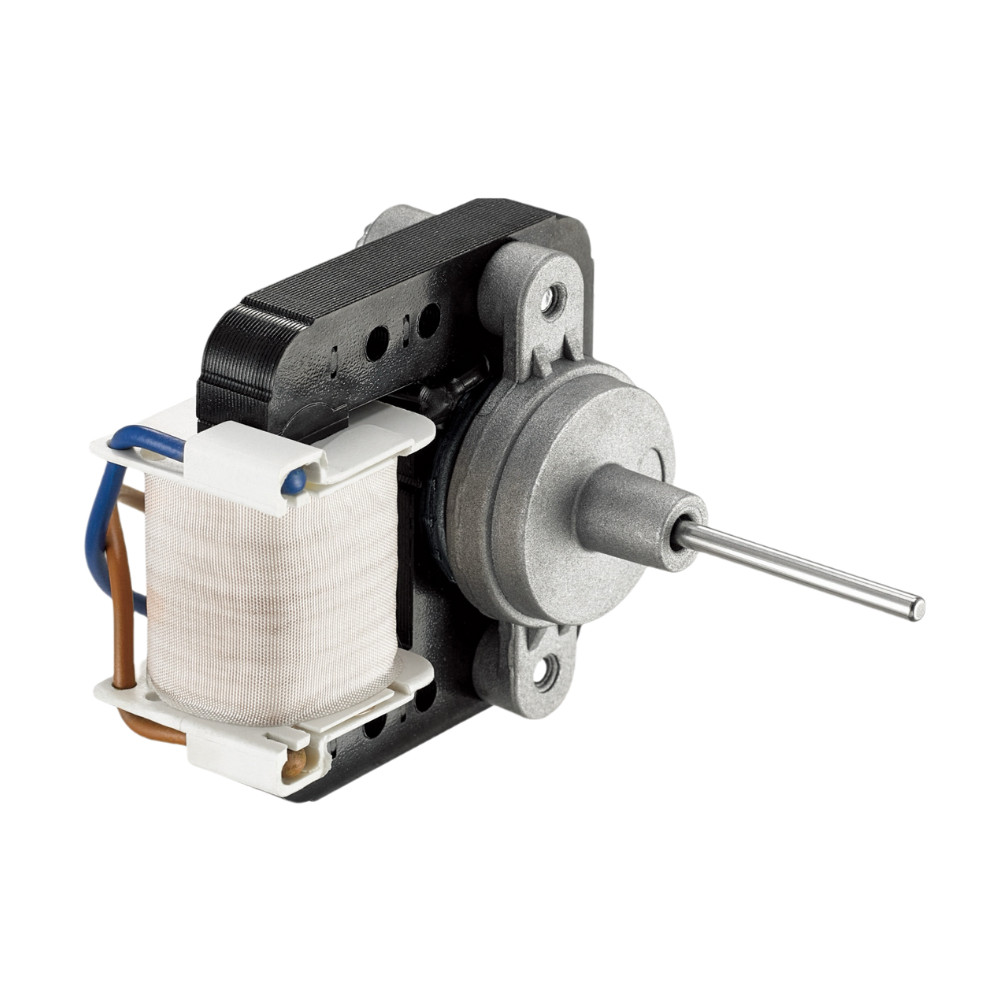

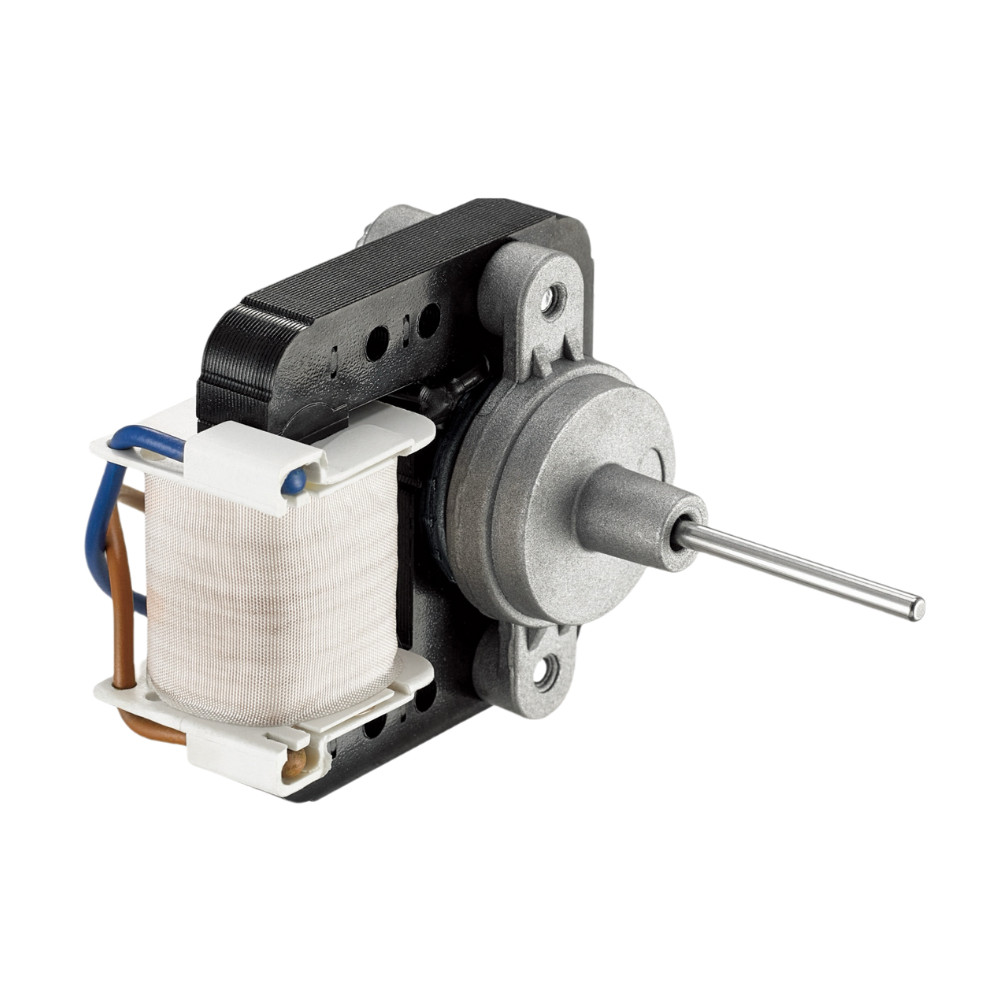

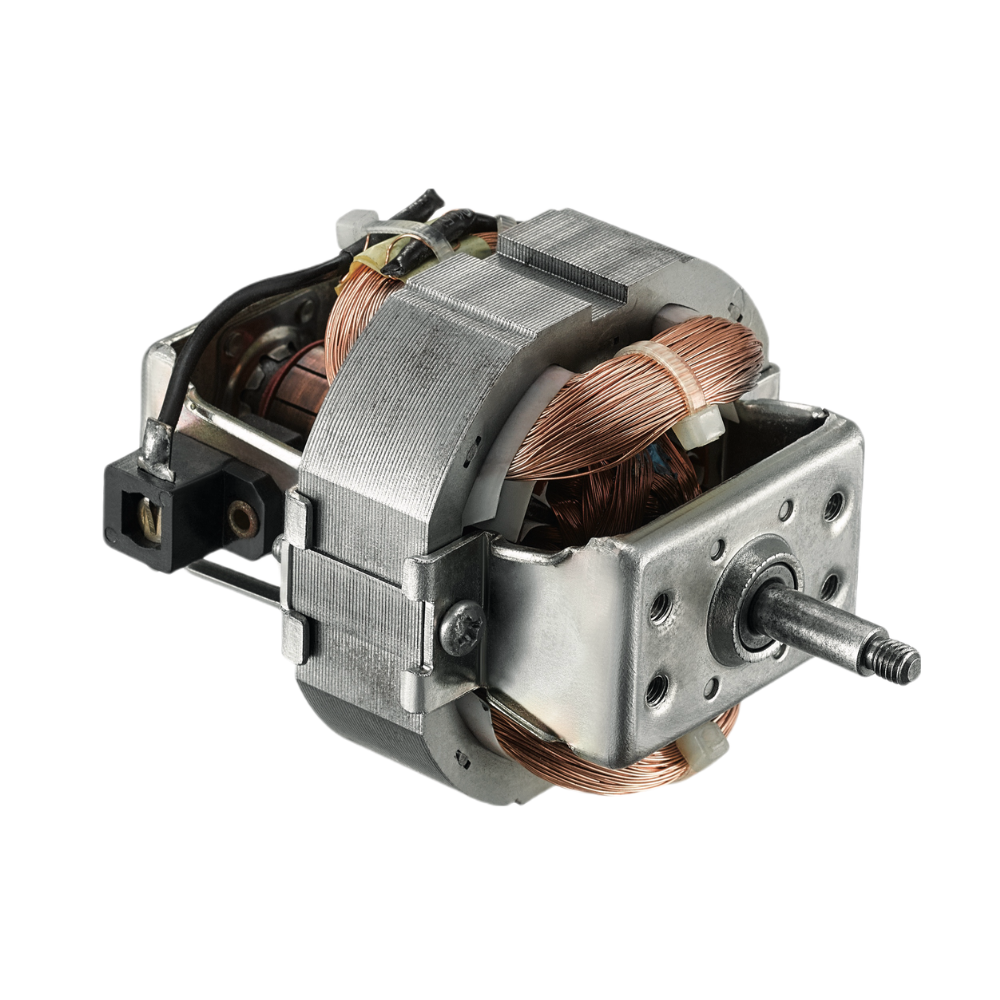

Industrial electrical motors are commonly used for driving machinery and equipment in various industrial applications, such as pumps, fans, conveyors, and compressors. They are essential in manufacturing, agriculture, and transportation sectors.

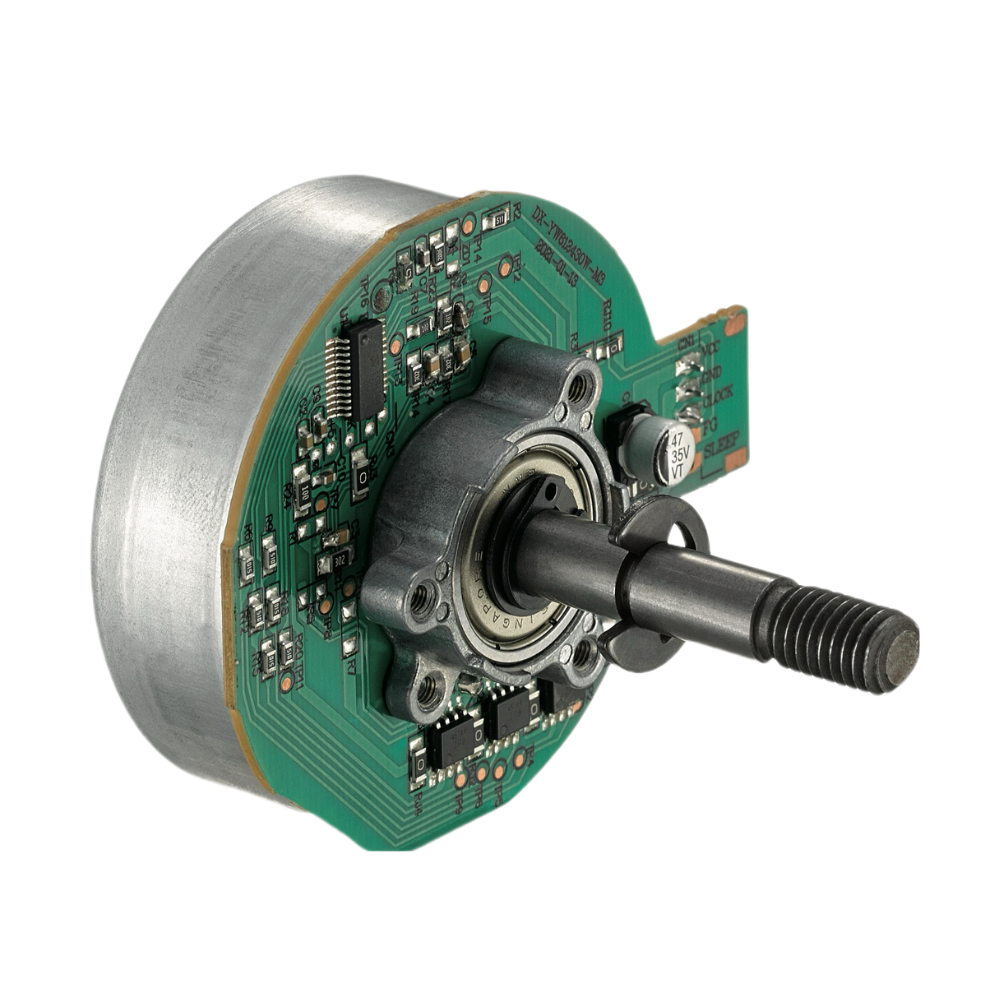

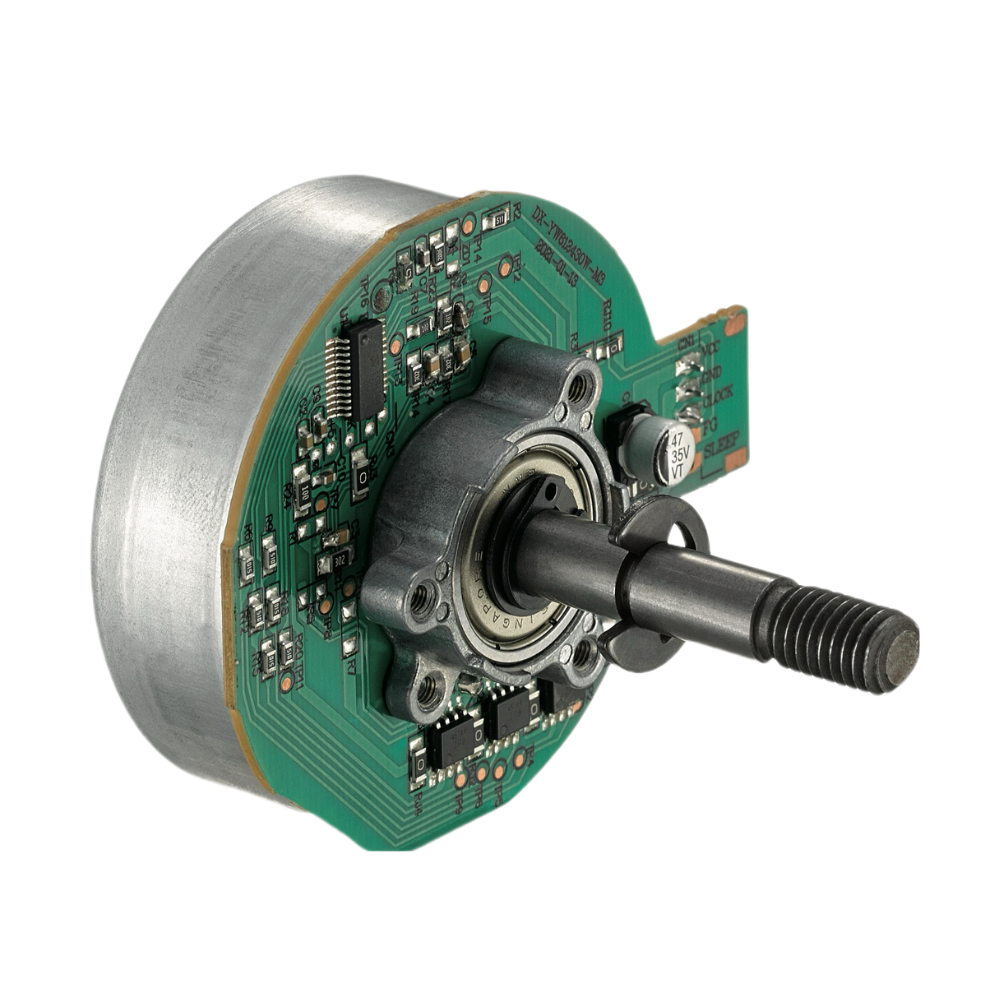

The main types of industrial electrical motors include AC motors (such as induction and synchronous motors) and DC motors (such as brushed and brushless motors). Each type has its own advantages and specific applications.

Selecting the right industrial electrical motor involves considering factors such as the required torque, speed, power supply, efficiency, and environmental conditions. It’s also important to match the motor’s specifications with the application’s demands.

Maintenance for industrial electrical motors typically includes regular inspections, cleaning, lubrication of bearings, checking electrical connections, and monitoring temperature and vibration levels to ensure optimal performance and longevity.

Lepu Motor is at the forefront of innovation, providing insights into industrial electrical motors to help you stay informed.

Owning a factory and top-notch technologies, Lepu Motor always offers unmatchable industrial electrical motors all over the world. Our excellent management, strong technical capability and strict quality control system, help to provide our clients with reliable quality, we accept and consider all orders with unique specifications, our OEM-standard products successfully undergoes professional certification. Many clients came to visit our factory and place orders. We warmly welcome you to contact us and please feel free to speak out your needs With a rich history spanning decades, our factory is known for innovative technologies, ensuring high-quality to excellence. We are looking forward to cooperating with you and providing our best services for you, as well as our industrial electrical motors, Industrial servo motor,Cross-Flow Fan. We’ve been honest and open up, dedication to high-quality is our life, customer first’ is our motto. We are eager to cooperate with foreign companies which care much on the real quality, stable supply, commercial esteem. We supply our industrial electrical motors worldwide, with markets including South Asia, West Africa, United States, Western Europe, etc.

Industrial electrical motors are crucial components in a wide array of manufacturing and production processes. These machines convert electrical energy into mechanical energy, facilitating motion and automation in various applications, from conveyor belts to heavy machinery. Given their significance, understanding the types, functioning, and efficiency of electrical motors is essential for optimizing industrial operations. Different motor types, such as AC, DC, and stepper motors, offer distinct advantages depending on the specific requirements of an application. As industries evolve towards increased automation and energy efficiency, the role of electrical motors becomes even more critical, necessitating continuous innovation and improvement in motor technology.