High-quality odm & oem industrial dc servo motor from lepu motor | low moq & fast delivery search lepu motor, who provides innovative industrial dc servo motor. we devote to industrial dc servo motor market for several yrs.

High-quality odm & oem industrial dc servo motor from lepu motor | low moq & fast delivery search lepu motor, who provides innovative industrial dc servo motor. we devote to industrial dc servo motor market for several yrs.

Discover Top-notch industrial dc servo motor at Lepu Motor. If industrial dc servo motor are your priority, Lepu Motor offers reliable industrial dc servo motor to explore.

Our highly recommended industrial dc servo motor are in demand among customers from around the world.

Our production facilities produce top-notch, long-lasting, and low-maintenance jigh-performance. Explore our website for additional details.

Lepu Motor collaborates with universities and Higen Motors, holding nearly 200 patents

We provide complete small appliance design, integrating Lepu Motor’s technology

30 + Countries Exported, 200 + Motor Models, 130 + Certified Technician, 4.8 Review Client

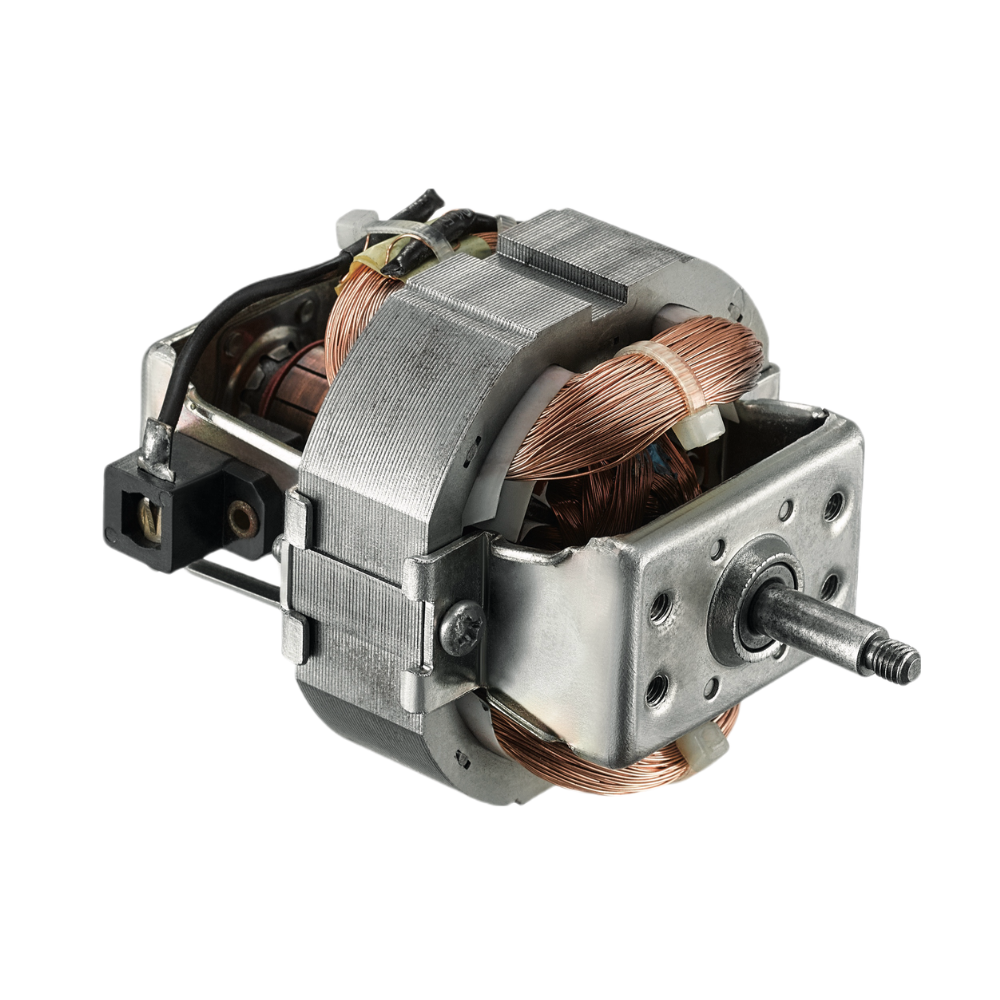

An industrial DC servo motor is a type of electric motor that uses direct current (DC) to provide precise control of angular position, velocity, and acceleration. These motors are commonly used in automation and robotics applications for their high performance and accuracy.

The main components of a DC servo motor include the stator, rotor, commutator, brushes, and feedback devices such as encoders or resolvers that provide position and speed information.

A DC servo motor operates on direct current and generally provides better torque at lower speeds, while an AC servo motor operates on alternating current and is often used for higher speed applications. Each has its advantages depending on the specific application requirements.

Industrial DC servo motors are commonly used in applications such as CNC machinery, robotics, conveyor systems, and any system requiring precise motion control and feedback for accurate positioning.

Explore how Lepu Motor enhances your understanding of industrial dc servo motor through cutting-edge solutions and expert knowledge.

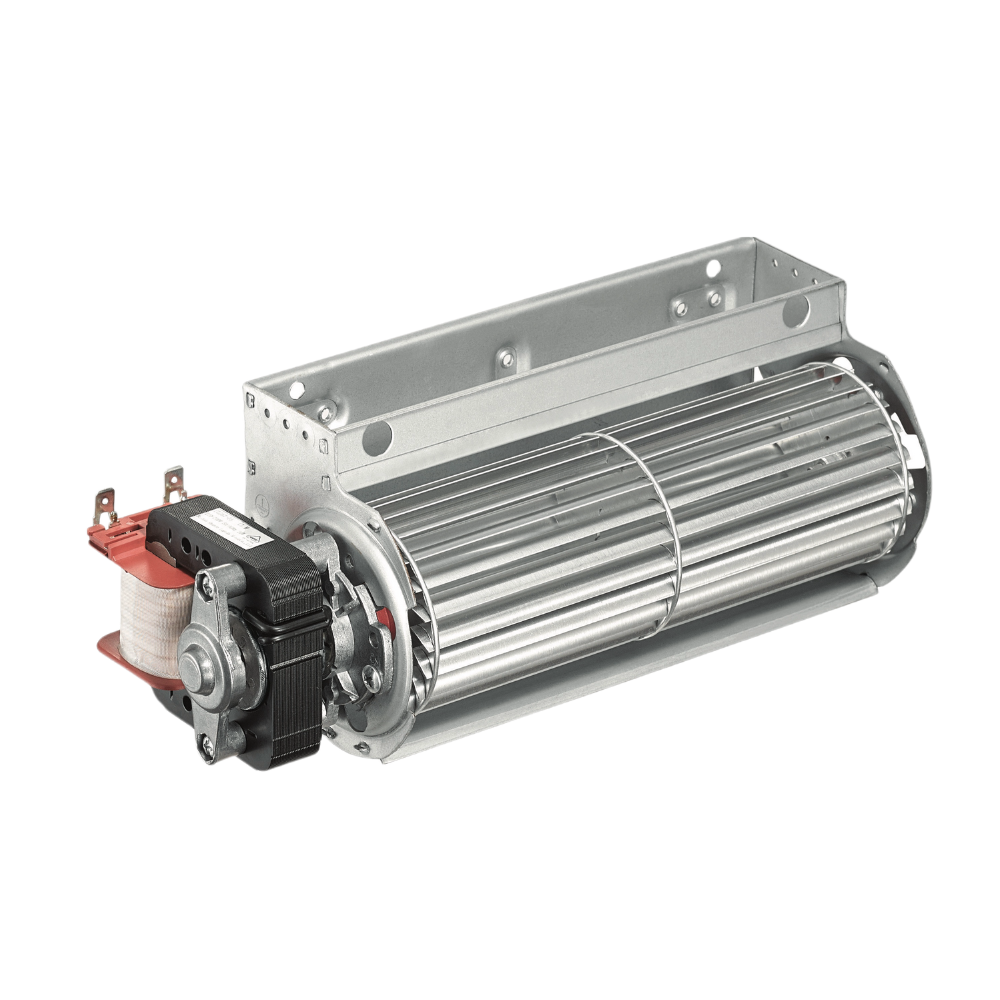

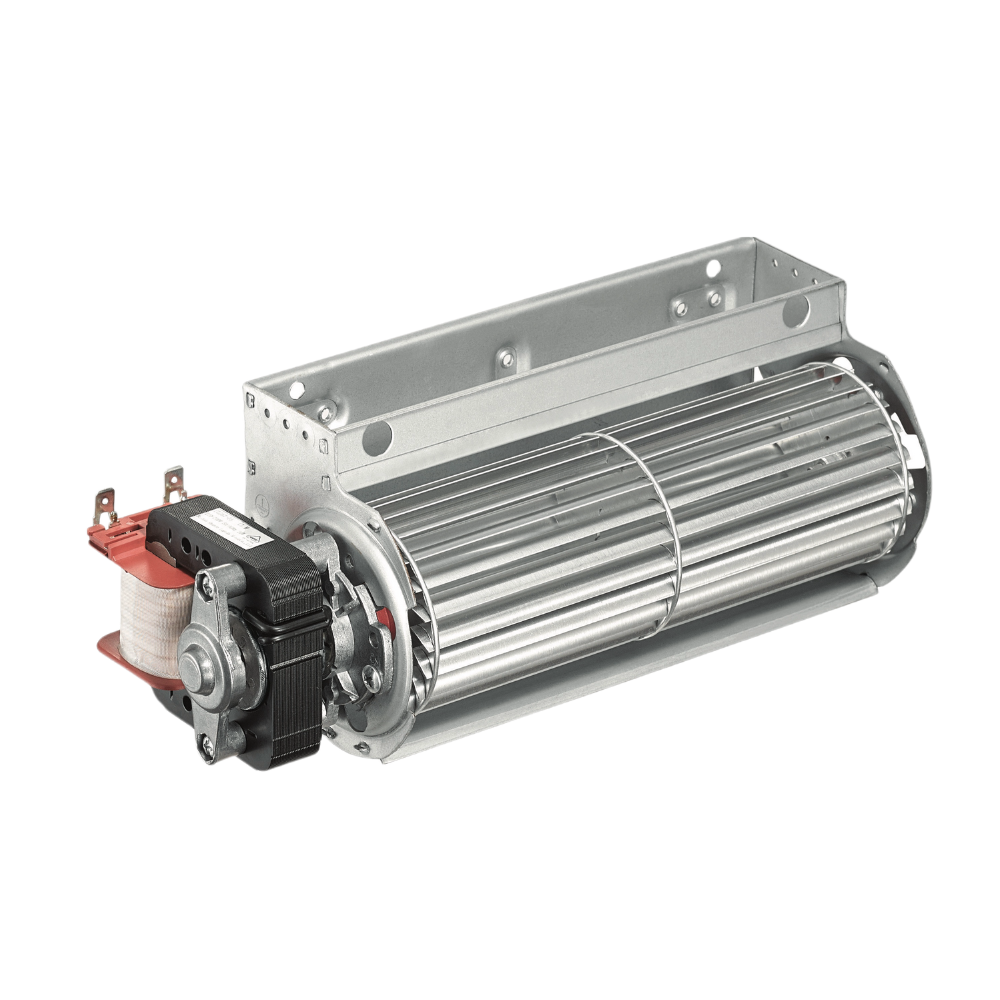

As a professional manufacturer, we are capable of meeting your requirements, we welcome all custom orders, our OEM-standard products successfully undergoes professional certification. We welcome new and previous clients from all walks of lifestyle to get in touch with us for long term business relationships and mutual accomplishment! We expect to provide industrial dc servo motor and services to more users in global markets including East Asia, North Africa, Brazil, New Zealand, etc. We will continue to carry forward the spirit of high quality, efficiency, innovation, integrity, the service is the vitality. trust paves our way to success. Owning a factory and top-notch technologies, Lepu Motor always offers unmatchable industrial dc servo motor all over the world. Your request is our command! If you are interested in any of our products, please feel free to contact us. Through recent years, our factory continues to lead the way cutting-edge technologies, maintaining the highest levels of professional competence. We are looking forward to cooperating with you and providing our best services for you, as well as our industrial dc servo motor, Industrial servo motor,Cross-Flow Fan.

Industrial DC servo motors are precision electromechanical devices widely utilized in automated systems for motion control. These motors operate on the principles of direct current, providing high torque and rapid response times across various applications, including robotics, CNC machinery, and conveyor systems. Their intrinsic capability to control speed and position with remarkable accuracy makes them indispensable in scenarios that demand strict performance criteria. With features such as feedback mechanisms and integrated controllers, DC servo motors enable seamless integration into advanced control systems, facilitating efficient operation in complex industrial environments. Their robustness and reliability under diverse conditions further enhance their appeal for manufacturers seeking optimized performance and productivity.