Top-quality odm & oem drive system motor from lepu motor | free samples lepu motor, offering innovative drive system motor with plenty yrs experience. the best drive system motor!

Top-quality odm & oem drive system motor from lepu motor | free samples lepu motor, offering innovative drive system motor with plenty yrs experience. the best drive system motor!

Upgrade with Top-notch drive system motor from Lepu Motor. Lepu Motor offers drive system motor that should be on your radar for drive system motor.

We are a global supplier of jigh-performance drive system motor to a diverse customer base.

We craft our great value for money with excellence, ensuring durability and minimal upkeep. Visit our website to learn more.

Our automated production base, supported by big data and intelligent systems like QMIS, TQM, and FMEA

We provide complete small appliance design, integrating Lepu Motor’s technology

30 + Countries Exported, 200 + Motor Models, 130 + Certified Technician, 4.8 Review Client

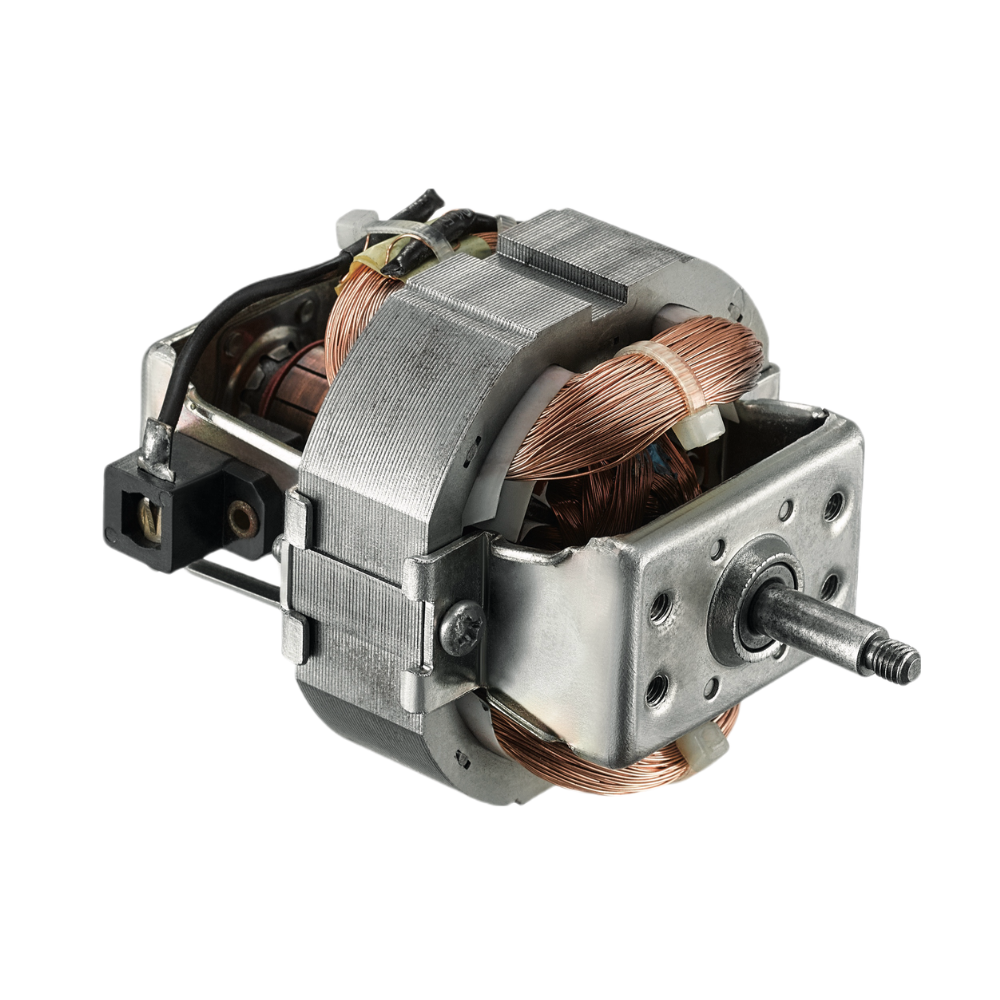

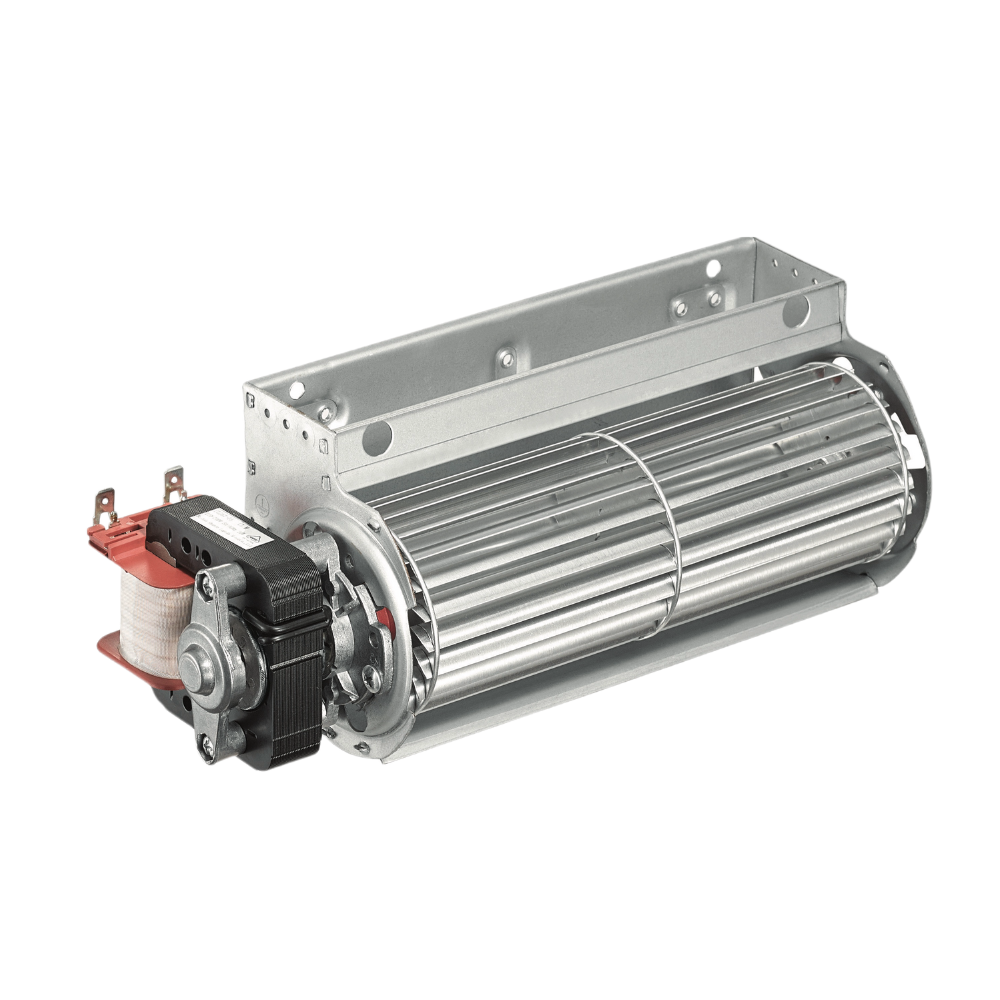

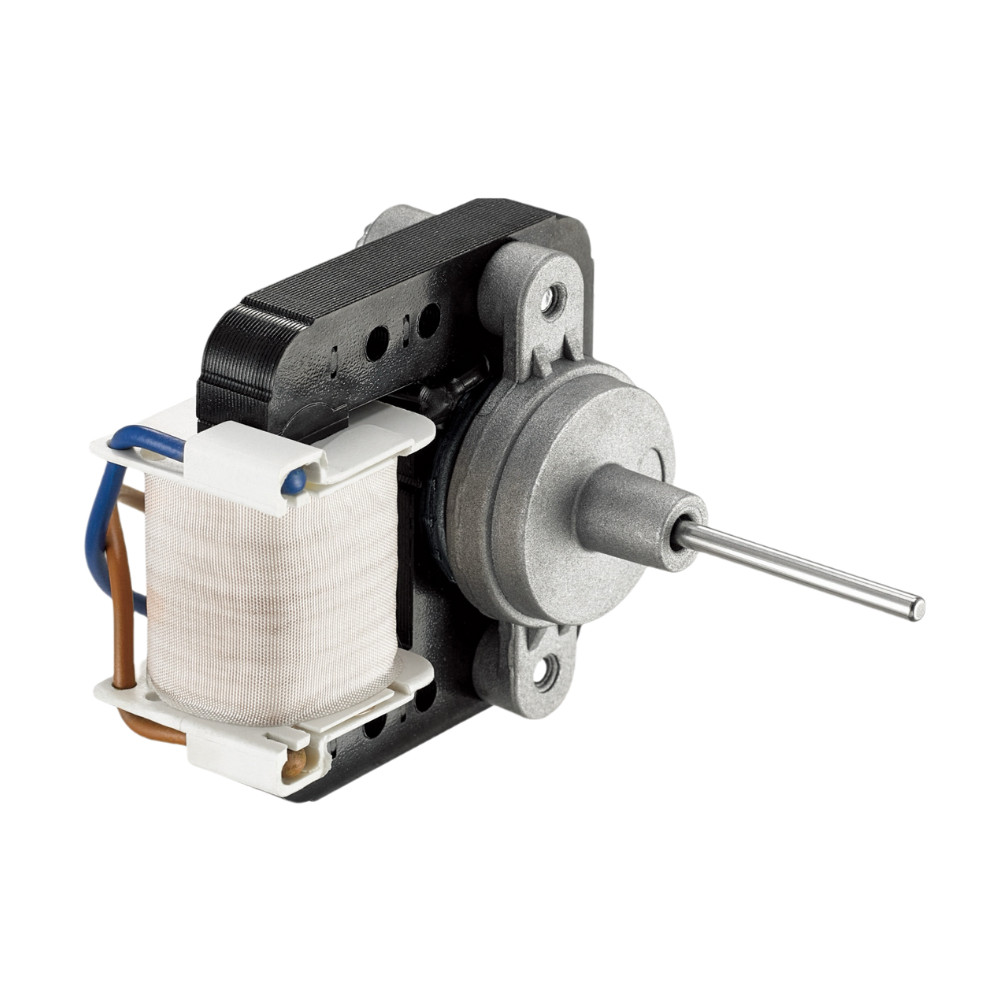

A drive system motor is an electric motor that converts electrical energy into mechanical energy to drive machinery or equipment, often used in industrial applications for automation.

A drive system motor works by using electrical current to create a magnetic field that causes the rotor to turn, thus producing mechanical motion that can be used to drive various loads.

Common types of drive system motors include AC motors, DC motors, stepper motors, and servo motors, each suited for different applications and control requirements.

The advantages of using a drive system motor in automation include precise control of speed and torque, energy efficiency, reduced maintenance, and the ability to easily integrate with control systems for optimized performance.

Lepu Motor combines expertise in drive system motor with practical solutions, empowering you to navigate this exciting field.

Owning a factory and top-notch technologies, Lepu Motor always offers unmatchable drive system motor globally. We sincerely welcome clients from at home and abroad, service is our goal, customer first’ is our motto. Now, with the trend of internationalization, we’ve got decided to establish a strong presence in international markets. Our drive system motor will supply to many countries and areas, including West Asia, South Africa, United States, Australia, etc. With your kind help, we believe that we can create a bright future with you together. Any inquiry or comment is highly appreciated. With a rich history spanning decades, our factory absorbed and digested advanced technologies, ensuring high-quality to excellence. We are looking forward to cooperating with you and providing our best services for you, as well as our drive system motor, Water Pump Motor,Cross-Flow Fan. Our R&D team has extensive experience to provide you expert support, feel free to tell us your special requests or concerns, all products have passed professional certification.

In the realm of rapid prototyping, understanding the intricacies of drive system motors is paramount for optimizing performance and ensuring reliability. These motors serve as the backbone of motion control, translating electrical energy into mechanical movement with precision. Typically categorized into two primary types—stepper motors and servo motors—each possesses distinct characteristics that cater to various application requirements. Stepper motors excel in open-loop control systems, providing precise positioning and repeatability, which is essential for tasks requiring fine adjustments. On the other hand, servo motors are integrated with feedback mechanisms, enabling closed-loop control that enhances speed, torque, and overall efficiency. As designers and engineers delve into the development of prototypes, the selection and integration of the appropriate drive system motor can significantly impact the functionality and success of the final product.