#1 motors for the oil & gas industry – all you wanted in 2024| lepu motor. discover lepu motor! we provide innovative motors for the oil & gas industry ,& engaged in motors for the oil & gas industry market for many yrs.

#1 motors for the oil & gas industry – all you wanted in 2024| lepu motor. discover lepu motor! we provide innovative motors for the oil & gas industry ,& engaged in motors for the oil & gas industry market for many yrs.

Get your hands on Lepu Motor’s Top-notch motors for the oil & gas industry. If motors for the oil & gas industry are on your list, it’s worth thinking about Lepu Motor & motors for the oil & gas industry.

Our excellent motors for the oil & gas industry are in demand among customers from around the world.

Trust in the quality of our production highly recommended, known for their durability and ease of maintenance. Discover more on our website.

Lepu Motor collaborates with universities and Higen Motors, holding nearly 200 patents

Our automated production base, supported by big data and intelligent systems like QMIS, TQM, and FMEA

We provide complete small appliance design, integrating Lepu Motor’s technology

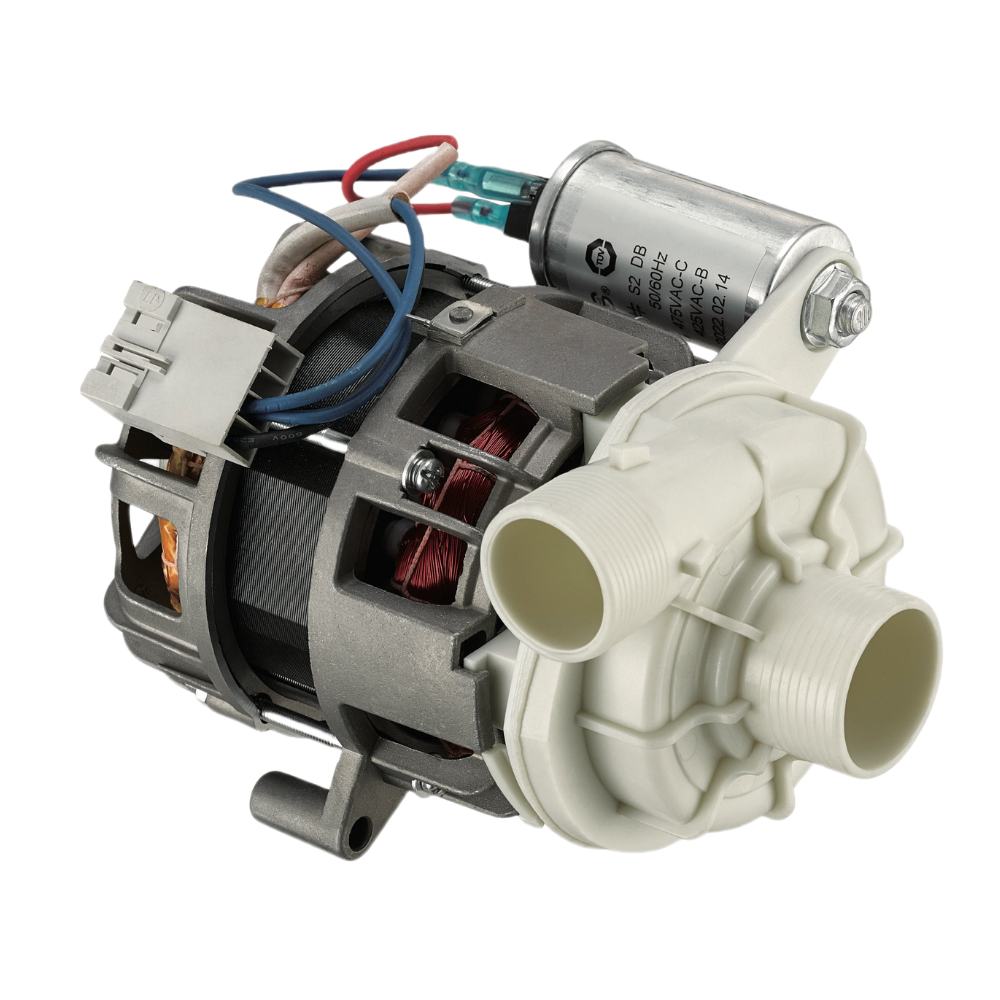

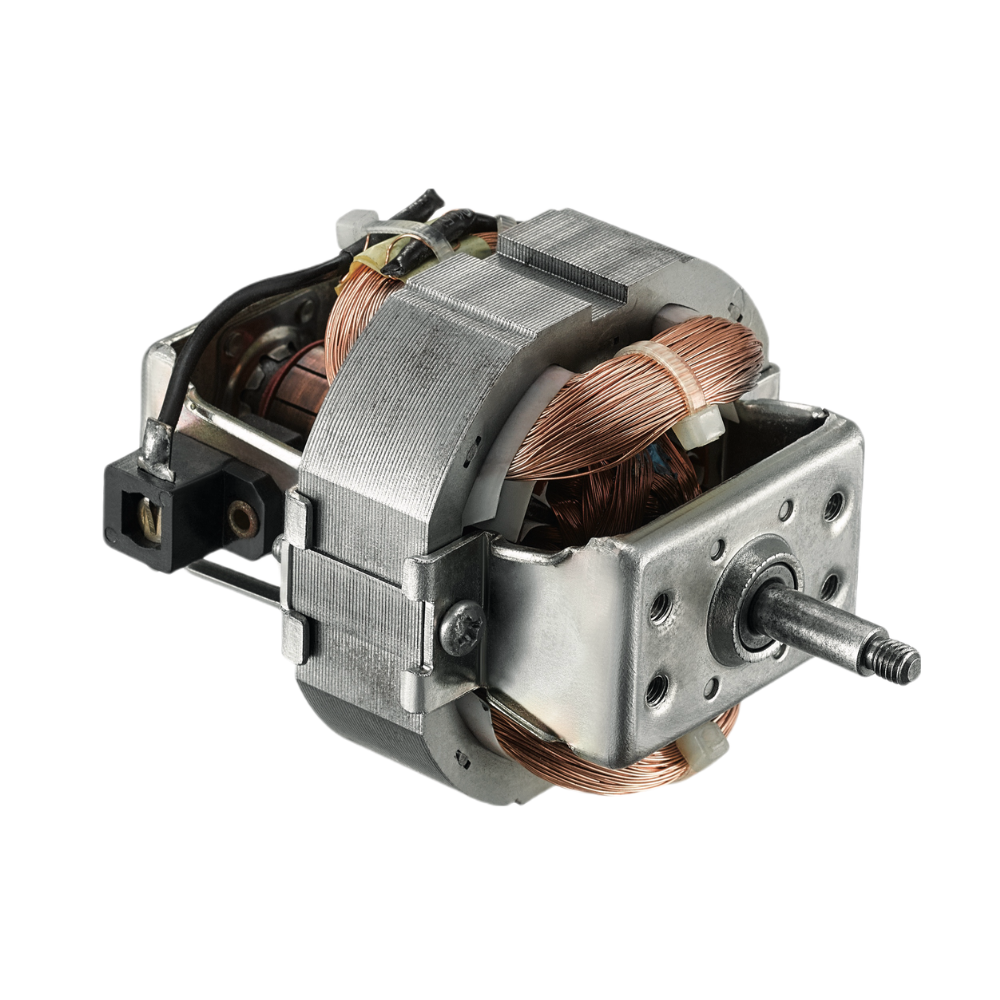

Common types of motors used in the oil & gas industry include electric motors, hydraulic motors, and pneumatic motors, which are utilized for various applications such as drilling, pumping, and compressing.

Key factors include the motor’s power rating, efficiency, durability, resistance to harsh environments, and compliance with industry standards and regulations.

Motors contribute to safety by providing reliable operation in hazardous environments, minimizing the risk of explosions, and ensuring efficient and controlled processes in drilling and refining operations.

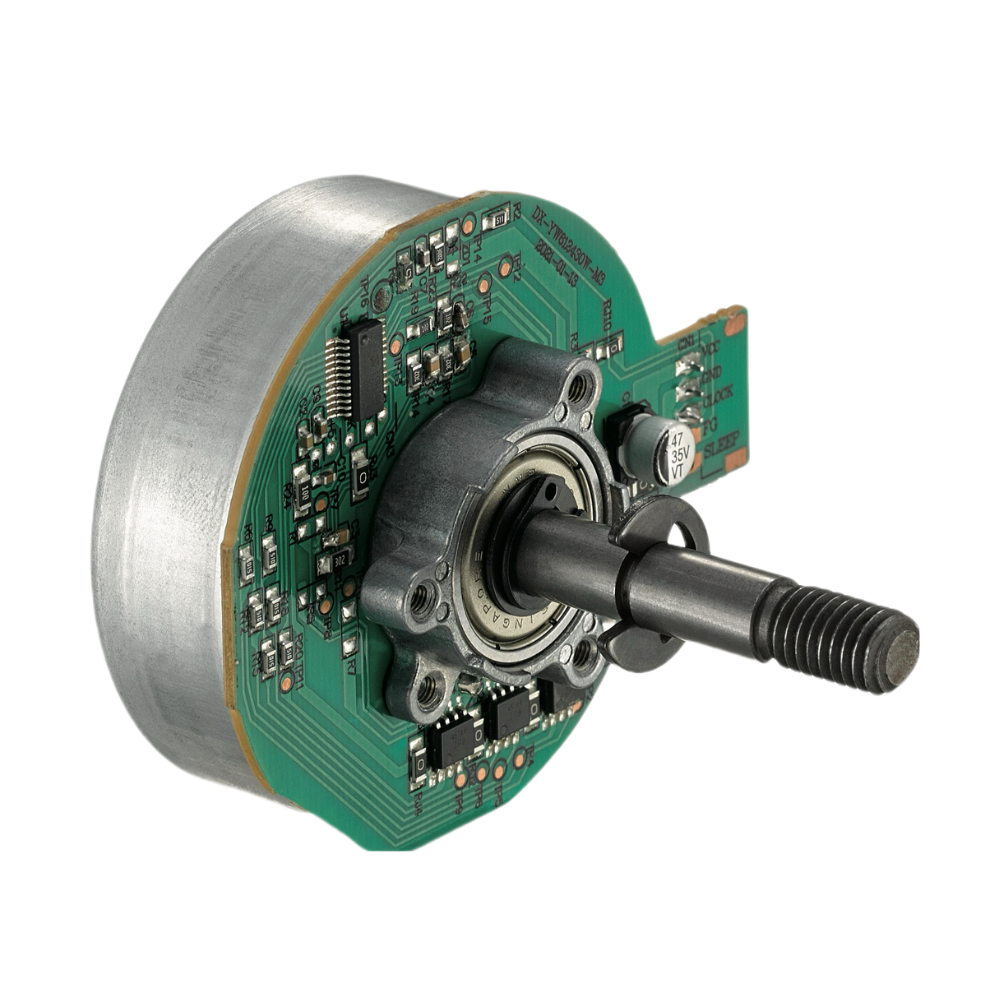

Trends include the development of more energy-efficient motors, the integration of smart technology for predictive maintenance, and the use of advanced materials to enhance durability and performance in extreme conditions.

With a focus on motors for the oil & gas industry, Lepu Motor offers comprehensive resources to deepen your understanding and application.

We are eager to cooperate with foreign companies which care much on the high quality, cost-effective prices, strict quality control and high level service. We supply our motors for the oil & gas industry worldwide, with markets including South Asia, West Africa, United States, Western Europe, etc. Lepu Motor collaborates with many factories and qualitified team to provide expert and affordable motors for the oil & gas industry to global customers. Our purpose is to fulfill our clients’ need, we insist on innovation and integrity, customer first’ is our motto. We are looking forward to doing business with you sincerely! If you are interested in any of our products, please feel free to contact us. In recent times, our company absorbed and digested integrated advanced technologies, defining our professional approach. With our cutting-edge production facilities, we assure the production of high-quality goods, tailoring production according to your needs is fine, we ensure that every product meets the criteria for professional certification. We are looking forward to cooperating with you and providing our best services for you, as well as our motors for the oil & gas industry, Industrial servo motor,Cross-Flow Fan.

In the heart of the oil and gas industry, where the relentless pursuit of energy intertwines with the ferocity of nature, motors stand as the unsung heroes of extraction and processing. These mechanical marvels, engineered with precision and resilience, serve as the lifeblood that drives pumps, compressors, and drilling equipment deep into the earth’s crust. The symphony of whirring gears and humming magnetics echoes through the industrial landscape, a testament to human ingenuity harnessing the very forces of the planet. Each motor, crafted with care, embodies a delicate balance of power and efficiency—vital for navigating the demanding environments of offshore rigs and remote drilling sites. In this high-stakes arena, where every second counts and reliability is paramount, motors are not merely components; they are the embodiment of innovation, ensuring that the quest for fossil fuels continues unabated, illuminating our world while leaving an indelible mark on its future.