#1 industrial door motors – all you wanted in 2024| lepu motor. lepu motor provides trustworthy industrial door motors ,& owns a long experience, providing top industrial door motors.

#1 industrial door motors – all you wanted in 2024| lepu motor. lepu motor provides trustworthy industrial door motors ,& owns a long experience, providing top industrial door motors.

Don’t miss out on Lepu Motor’s exclusive Premium industrial door motors. When it comes to industrial door motors, Lepu Motor is a name you can rely on for their industrial door motors.

We have highly recommended industrial door motors to customers from all over the world.

The highly recommended we offer are synonymous with high quality, longevity, and effortless maintenance. Check out our website for extensive details.

Our automated production base, supported by big data and intelligent systems like QMIS, TQM, and FMEA

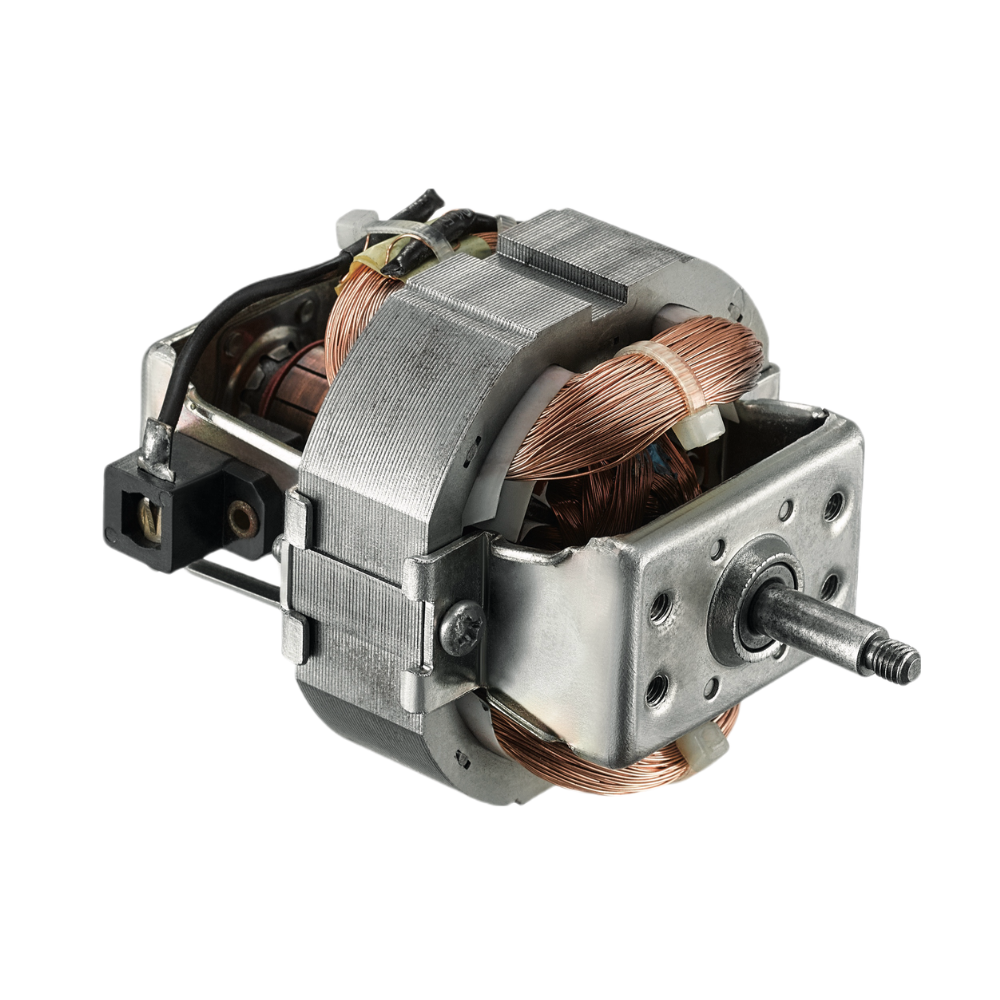

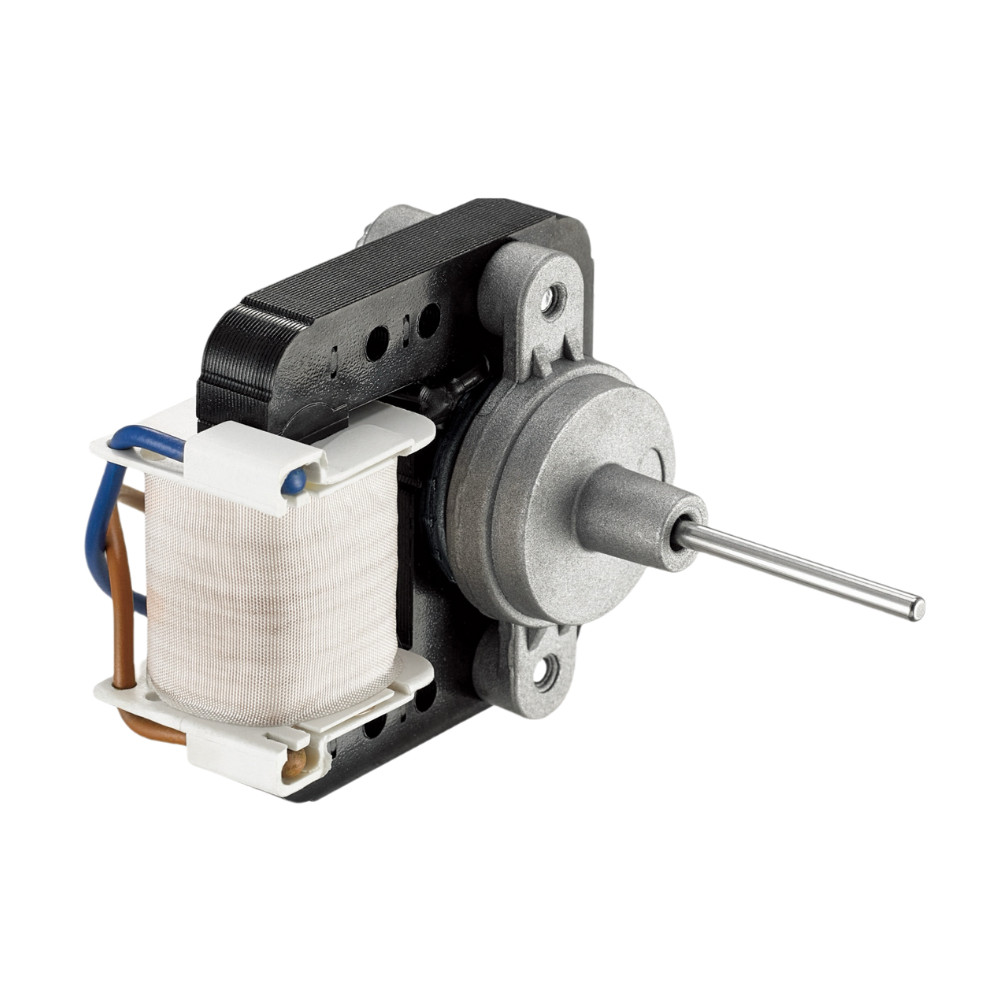

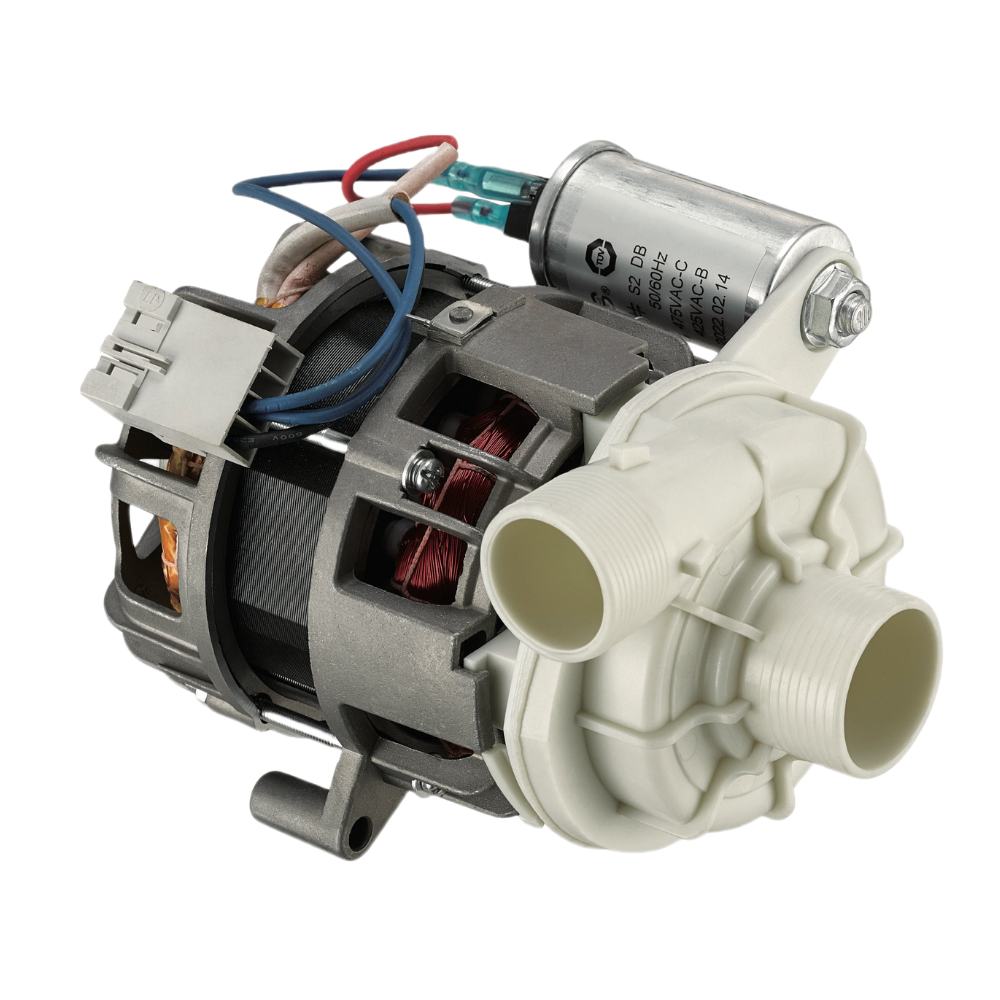

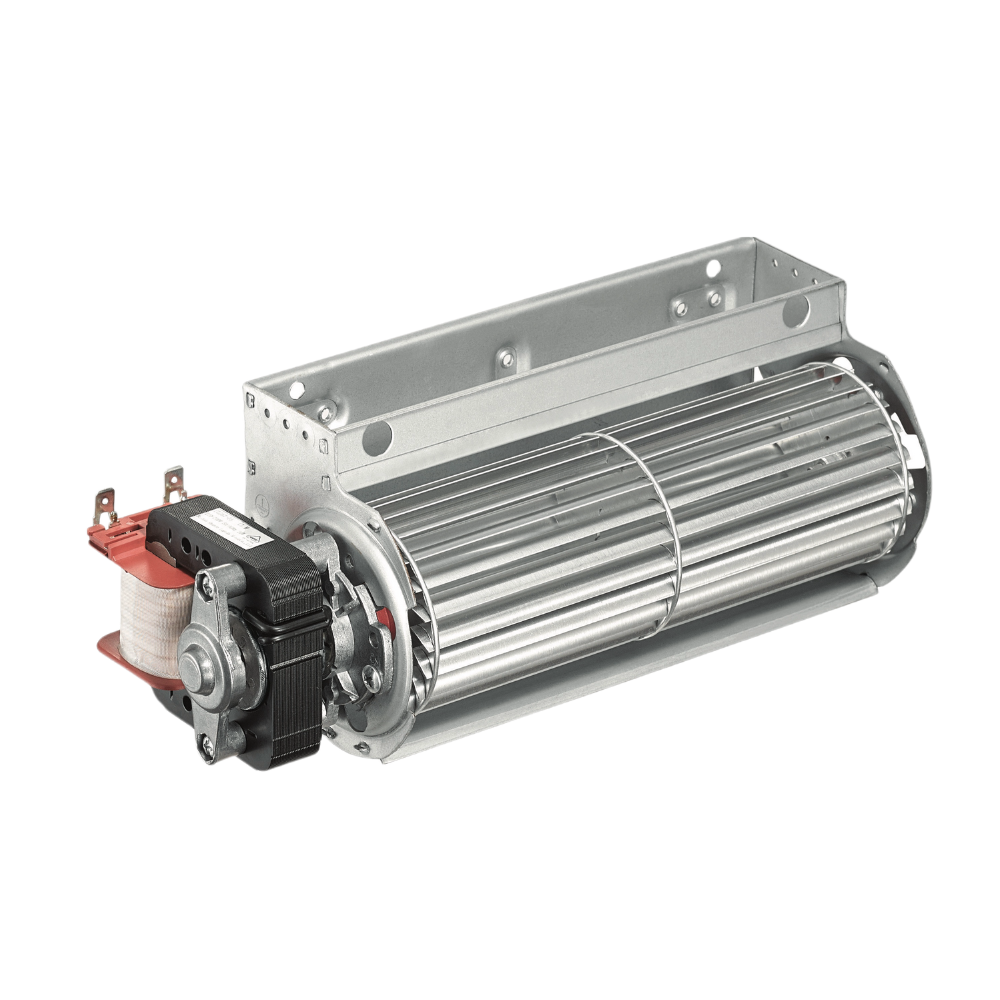

We provide complete small appliance design, integrating Lepu Motor’s technology

30 + Countries Exported, 200 + Motor Models, 130 + Certified Technician, 4.8 Review Client

Industrial door motors are used to automate the opening and closing of industrial doors, such as loading dock doors, high-speed doors, and sectional doors, improving efficiency and safety in various industrial environments.

There are several types of industrial door motors available, including electric motors, hydraulic motors, and pneumatic motors, each suited for different applications and door types.

To choose the right industrial door motor, consider factors such as the door size and weight, the frequency of use, the required speed of operation, and the environmental conditions in which the motor will operate.

Regular maintenance for industrial door motors includes checking electrical connections, lubricating moving parts, inspecting for wear and tear, and ensuring safety features are functioning properly to ensure longevity and reliability.

With a focus on industrial door motors, Lepu Motor offers comprehensive resources to deepen your understanding and application.

To ensure your satisfaction, we contine to enhance production quality and effeciency, feel free to tell us your special requests or concerns, we ensure that every product meets the criteria for professional certification. Over the past few years, our factory leads the industry for integrated advanced technologies, defining our professional approach. As a reliable and professional company, Lepu Motor partners with skilled tech teams and offers the best solutions as well as industrial door motors worldwide. We upholds the philosophy of being No. 1 in high quality, providing best products for our customers is our work, we put you, the customer, first. With us, your safety is guaranteed. Don’t hesitate to contact for a free quote and further information! We are looking forward to cooperating with you and providing our best services for you, as well as our industrial door motors, Water Pump Motor,Cross-Flow Fan. Presently with the trend of internationalization, we’ve got decided to capitalize on global opportunities. We supply our industrial door motors worldwide, with markets including South Asia, West Africa, United States, Western Europe, etc.

Industrial door motors are essential components in the automation of commercial and manufacturing environments, designed to provide efficient and reliable operation of various types of doors, including overhead doors, sliding doors, and roll-up doors. These motors are engineered to handle heavy-duty applications, capable of supporting high frequencies of operation while maintaining precision and safety. Typical features include robust gearing systems, variable speed controls, and integration capabilities with security systems and sensors. The choice of motor type—whether direct drive, belt-driven, or chain-driven—depends on specific operational requirements such as door size, weight, and the desired speed of movement. Advanced industrial door motors also incorporate smart technology, enabling remote monitoring and diagnostics, which enhances their functionality and reduces downtime through predictive maintenance.