Growth and Demand in the Micro Motor Market

The global micro motor market is experiencing robust growth, with projections indicating that the market will expand from $47.2 billion in 2024 to $77.5 billion by 2030, at a compound annual growth rate (CAGR) of 8.6%. This growth is fueled by the rising demand for micro motors in various applications, including automotive, medical equipment, industrial automation, and consumer electronics. The increasing urbanization and industrialization in emerging economies further bolster this demand.

Advantages of Micro Motors in Industrial Applications

Micro motors are valued for their compact size, high efficiency, and ability to minimize electromagnetic interference. These characteristics make them ideal for a wide range of industrial applications, including drilling, polishing, grinding, and more. The benefits of micro motors, such as high torque, low noise levels, energy savings, and increased operational efficiency, drive their adoption in the manufacturing sector.

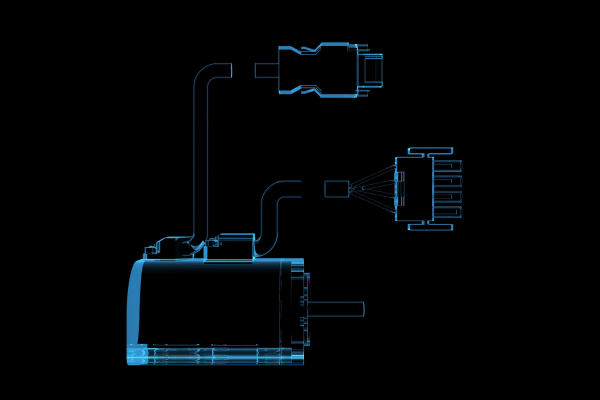

The Role of Industrial Servo Motors in Automation

Industrial servo motors are pivotal in powering the machinery that drives manufacturing processes. They convert electrical energy into precise mechanical motion, meeting the need for controlled movements in various robotic systems. Servo motors are particularly suited for high-precision tasks such as CNC machining, robotics, and automated inspection systems.

Types of Servo Motors

DC Servo Motors: Known for their simple design and ease of speed control, DC servo motors are ideal for applications requiring continuous and controlled motion.

AC Servo Motors: Preferred for high-power and constant-speed applications, AC servo motors are efficient and reliable.

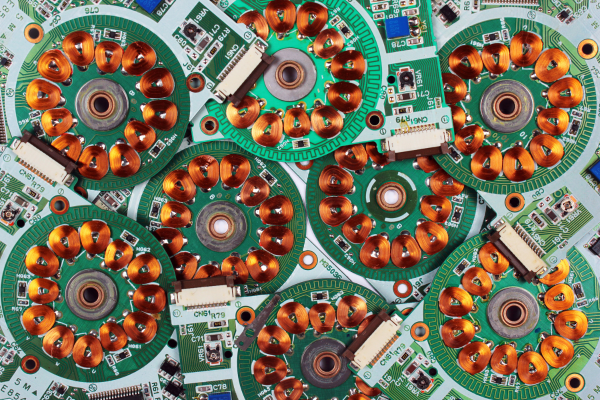

Brushless Servo Motors: These motors replace the mechanically driven functions of brushed motors with an electronic drive, offering higher efficiency and reliability.

Stepper Motors: These motors move in discrete steps and are ideal for applications requiring accurate positioning, such as 3D printing and medical devices

Integration of Servo Motors in Automated Manufacturing

The integration of servo motors into automated manufacturing equipment offers several advantages:

Precision and Control: Servo motors provide precise control over position, speed, and torque, essential for tasks such as robotic arm control and precision cutting in manufacturing processes.

Efficiency and Reliability: The use of brushless servo motors enhances the efficiency and reliability of manufacturing equipment, reducing maintenance costs and downtime.

Scalability and Flexibility: Servo motors enable scalable and flexible manufacturing processes, allowing for quick adjustments and reconfigurations to meet changing production needs.

Applications in Final Assembly Lines

In the context of final assembly lines for shaded pole motors, the use of servo motors can significantly improve the efficiency and precision of the assembly process. Servo motors can control the positioning and movement of components with high accuracy, ensuring consistent quality and reducing the risk of errors. This is particularly important in the production of shaded pole motors, where precise assembly is crucial for optimal performance.

Conclusion

The future trend of the micro motor industry is clearly moving towards the integration of industrial servo motors into automated manufacturing equipment. This trend is driven by the need for precision, efficiency, and scalability in manufacturing processes. As the demand for high-quality, efficient manufacturing solutions continues to grow, the role of servo motors in industrial automation will become increasingly important, paving the way for more advanced and efficient manufacturing systems.