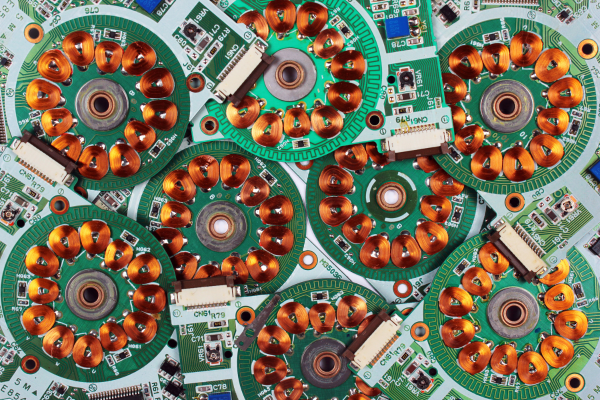

- Six-Axis Articulated Robot Solution:

Six-axis articulated robots, also known as jointed arm robots or jointed manipulators, are one of the most common forms of industrial robots today, suitable for mechanical automation tasks in various industrial fields. Each robot uses six servo motors, and different models are available depending on the robot’s arm length and the weight it can handle. The servo motors used range from several watts to several kilowatts.

- Application Field:Industrial Robots

- Solution Description:Six-axis articulated robots require servo motors with high torque, high speed, compact size, low torque ripple, high response speed, and reliability for long-term, uninterrupted operation. Our KS series (selected models) servo motors use a magnetic ring structure in the rotor, achieving high speed and compact size without compromising torque, while also having excellent torque ripple characteristics. Our products cover a motor capacity range from 50W to 4.4kW, meeting the needs of most robot models.

- Solution Advantages:Comprehensive product range enables one-stop purchasing for customers, providing higher torque-speed characteristics under high reliability, improving robot operational efficiency while ensuring stable operation due to low torque ripple characteristics.

- SCARA Robot Solution:

SCARA robots, also known as Selective Compliance Assembly Robot Arms, are a special type of industrial robot with a cylindrical coordinate system, commonly used in high-speed assembly, handling, polishing, and packaging industries. These robots require very high operational cycle times, high speed, high responsiveness, and high overload capacity.

- Application Field:Industrial Robots

- Solution Description:Our company offers low-capacity motors with a maximum speed of 6000 rpm, enabling high-speed operation and shorter cycle times. These can be paired with a 23-bit multi-turn absolute encoder for high positioning accuracy. The motor’s excellent overload capacity also enables continuous operation under high load conditions.

- Solution Advantages:High speed and responsiveness shorten cycle times, while high overload capacity ensures stable equipment operation.

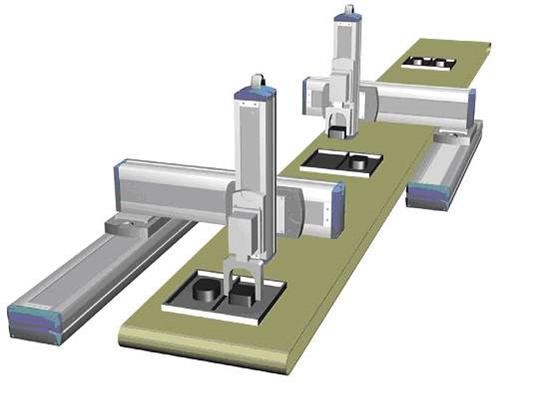

- Manipulator Solution:

Manipulators, also known as Cartesian robots, are generally used for material handling, sorting, and picking. They are further categorized into injection molding manipulators, machine tool manipulators, die-casting manipulators, stamping manipulators, etc., depending on the industry. Due to intense market competition, there are high demands on the performance and cost of servo motors.

- Application Field:Manipulators

- Solution Description:Our KJ series servo motors were designed with a balance between performance and cost in mind. Options include relatively low-cost magnet-type motors and optical incremental or magnetic encoders. However, to ensure basic motor performance, we have retained the 5-pole 10-slot structure found in high-performance servo motors within the industry, achieving a balance between performance and cost.

- Solution Advantages:Targeted at specific industries, providing excellent cost-performance while meeting performance requirements.

- Automatic Screw Tightening Machine Solution:

The three-axis screw tightening machine features a wide operational range, high flexibility, fast operating speed, and allows for manual dragging of the Z-axis for quick positioning of screw points, effectively solving issues like small spaces or large product sizes. Like many non-standard automated devices, it requires customized motors based on the equipment’s characteristics to improve production efficiency and achieve perfect motor-to-equipment matching. The client found that the motor’s built-in cables were too short, requiring extensions. The extension cable connectors inside the equipment became unstable factors, causing poor contact when the equipment was running, also posing some inconvenience during production.

- Application Field:Automation Equipment

- Solution Description:To enhance convenience during equipment assembly and reduce intermediate connectors, thereby improving equipment stability, the client requested customized motor cables and connectors. Our servo motors were tailored to the equipment’s requirements, providing customized cables and connectors, along with pin definitions matching the client’s driver.

- Solution Advantages:Flexible motor customization based on specific customer requirements to address client pain points.

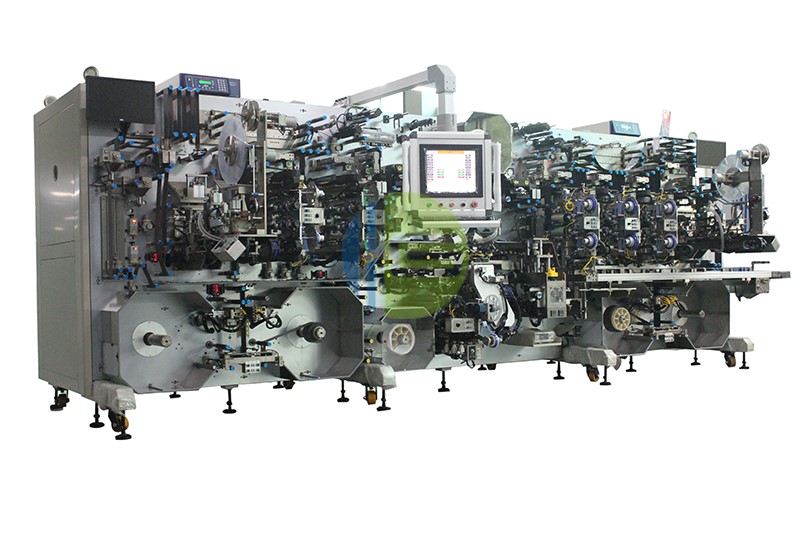

- Lithium Battery Production Equipment (Cell Winding Machine) Solution:

This equipment is used for making square lithium-ion battery cells. It performs actions such as automatic unwinding, automatic deviation correction, tension control, tab folding detection, winding, sticking terminal adhesive, CCD misalignment detection, short-circuit detection, unloading to the conveyor belt, etc., to complete cell production. Due to the need for automatic unwinding and high-precision tension control during production, there are high requirements for motor torque output stability and low torque ripple.

- Application Field:Automation Equipment

- Solution Description:Our 130 and 180 flange series motors also adopt the 10-pole 12-slot structure of small-capacity servos below the 80 flange. Although the product cost is high, this motor structure offers better real-time responsiveness, accommodating the equipment’s rapid acceleration and deceleration and tension adjustment actions. The low torque ripple characteristic of this structure also ensures stable torque output during motor operation.

- Solution Advantages:Fast motor response and low torque ripple.