With the continuous advancement of motor technology, the requirements for motor performance and reliability are also increasing. Foshan Shunde Lepuda Motor Co., Ltd. (referred to as Lepu Motor) has always been at the forefront of motor research and innovation. Its BMC encapsulation solution leads the revolution in motor packaging technology. This article will provide a detailed introduction to Lepu Motor’s BMC encapsulation solution and its advantages.

I.What is the BMC Encapsulation Solution?

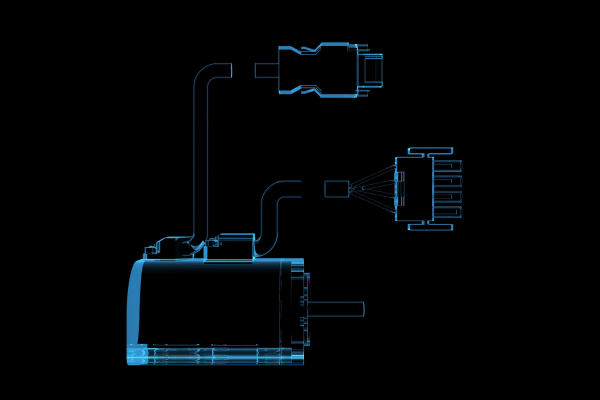

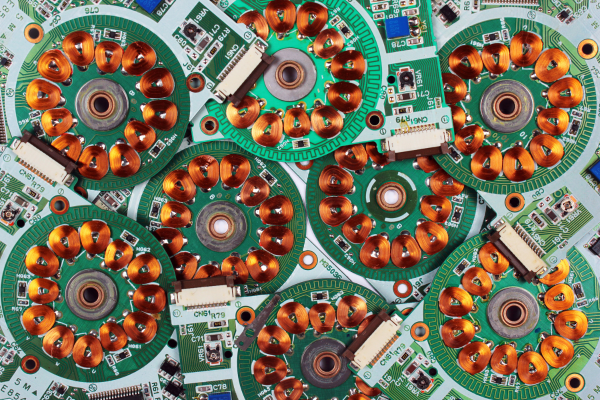

BMC (Bulk Molding Compound) is a thermosetting composite material mainly composed of chopped glass fibers, polyester resin, fillers, and additives. Lepu Motor’s BMC encapsulated motor uses BMC material for housing and component encapsulation, offering significant technical and performance advantages over traditional copper wire solutions.

II.Core Advantages of the BMC Encapsulation Solution

- Waterproof Capability:

The structure of BMC material is dense with small molecular gaps, making it difficult for moisture to penetrate. When motors are used in humid environments, the BMC encapsulation solution effectively prevents moisture ingress, ensuring long-term normal operation and reducing the risk of failures. This feature is especially crucial in applications that require high waterproof performance. - Anti-Oxidation:

BMC material provides a vacuum environment for the enameled wires inside the motor, preventing oxidation issues. Traditional copper wire solutions require varnish treatment for insulation, but the BMC encapsulation technology eliminates the need for such processes, removing the odor problems associated with varnishing. This not only enhances the user experience but also meets environmental and health standards. - Corrosion Resistance:

In salt spray tests, motors with the BMC + aluminum wire solution showed excellent corrosion resistance. After 360 hours of salt spray testing, the enameled wire weld joints of traditional copper wire motors exhibited severe oxidation, while the BMC encapsulated motor showed no defects even after 1000 hours of salt spray testing, with the motor performance remaining qualified. - High-Pressure Locked-Rotor Test:

The BMC encapsulated motor performed exceptionally well in high-pressure locked-rotor tests. Traditional copper wire motors started to short-circuit with visible smoke and sparks after 20 seconds at 160V, whereas the BMC encapsulated motor only began to short-circuit after 3 minutes at 230V, with no visible smoke or sparks, significantly reducing safety hazards. - Extended Motor Life:

The stator windings and weld joints of traditional copper wire motors are exposed to the air, and long-term operation can cause wire breakage due to current impact. In contrast, the internal windings and weld joints of the BMC encapsulated motor are in a vacuum-sealed state, greatly improving durability. Life tests show that the lifespan of BMC encapsulated motors can be extended from 8,000 hours to over 10,000 hours. - Temperature Rise Performance:

The BMC encapsulated motor exhibits better temperature rise performance than traditional copper wire motors. Tests show that motors using aluminum wires and BMC encapsulation technology have lower temperature rise, which not only enhances motor safety but also reduces energy consumption and improves overall efficiency.

Conclusion:

Lepu Motor’s BMC encapsulation solution demonstrates significant advantages in waterproofing, anti-oxidation, corrosion resistance, high-pressure locked-rotor testing, extending motor life, and temperature rise performance. This innovative technology enhances the performance and reliability of motors while providing a superior user experience. In the future, Lepu Motor will continue to promote the application and development of BMC encapsulation technology, striving to become a leader in the field of motors and intelligent drive control technology.